Brochures

LTR-3 technical leaflet eAir control brochure EcoDesign label EcoDesign product information leaflet LTR-3 eAir user instruction LTR-3 eAir installation instruction Design software runDimensional images

LTR-3 with 25 mm insulation dimension drawing (dwg) LTR-3 with 25 mm insulation dimension drawing (pdf) LTR-3 with 50 mm insulation dimension drawing (dwg) LTR-3 with 50 mm insulation dimension drawing (pdf) LTR-3 eAir E-CG control chart (dwg) LTR-3 eAir E-CG control chart (pdf) Dimension drawings all units (dwg)LTR-3 eAir E-CG

Ventilation unit with heat recovery, electrical after heater and duct cooler for cooled water. The unit is equipped with Enervent eAir control.

The Enervent LTR-3 unit is best suited for terraced houses and smallish detached houses. The LTR-series units are designed for installation in the roof, in the attic, in a false ceiling or in a technical space. The horizontal installation often saves a lot of space. LTR-series units are well insulated and can be installed in cold places. The unit needs additional insulation if the temperature around it drops below -10°C. The simple but ingenious structure and the low pressure drop of the unit ensure an inexpensive and safe operation.

General information

Air volume flow: 50…320 m³/h EcoDesign classification: A Reference flow rate according to EcoDesign directive (50 Pa): 224 m³/h

Pressure difference: 15 to 100 Pa

Leakage external: < 5% (test pressure 300Pa)

Leakage internal: < 5%

Duct size: Ø 160 mm

Weight: 52 kg

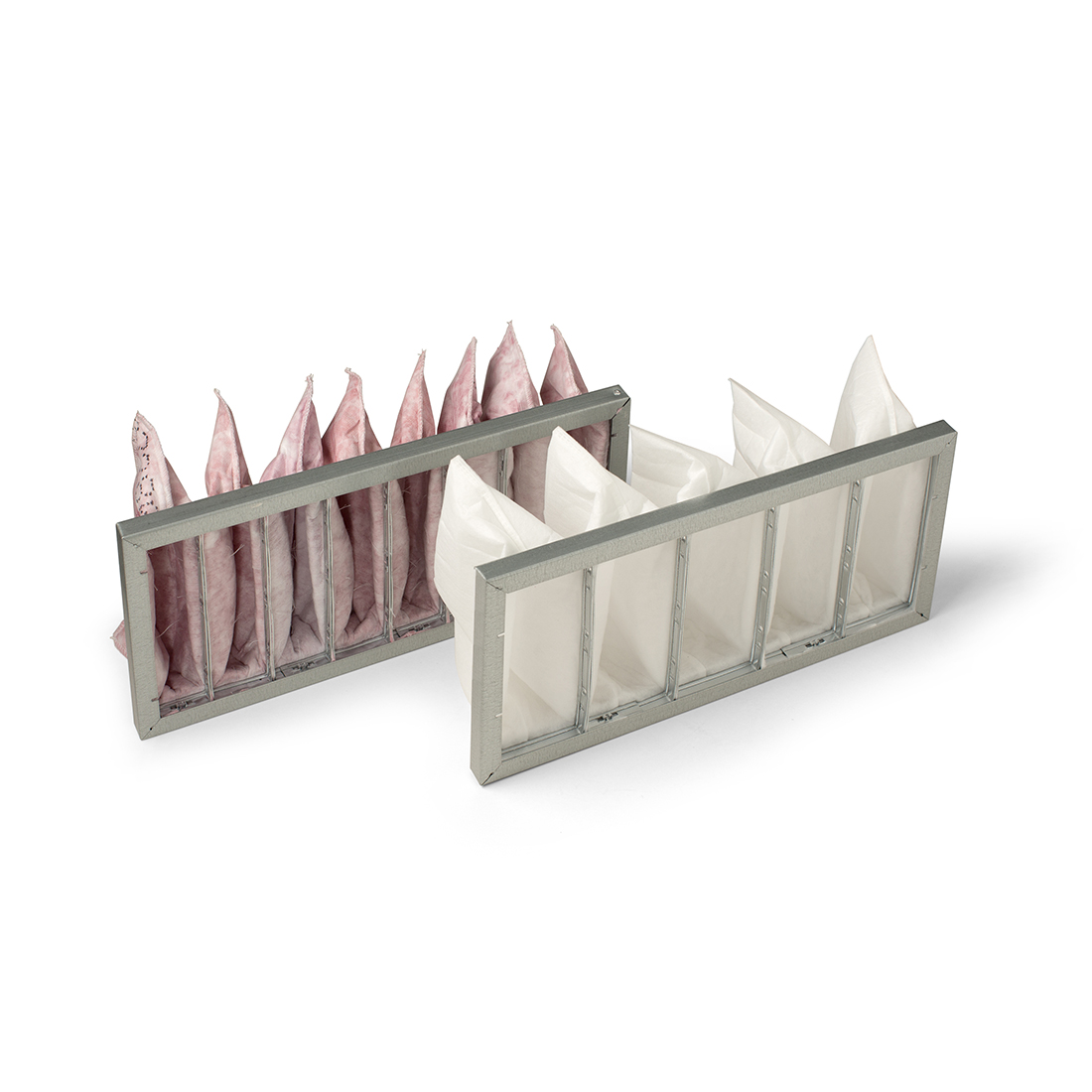

Standard filters: ISO ePM1 60 % / ISO Coarse 80 % (F7/M5)

IP class: IP44 (external control IP20)

Condense connection: ¼” internal thread

Nominal voltage: 230 V

Nominal current: Motors 1.8 A total, electrical after heating 2.1 A

Fans

Supply and exhaust air fan type: Ebm-Papst

Supply and exhaust air motor type: G3G146-ED19-10

Nominal voltage: 230 V (AC), EC-type with internal electronics

Type of fan blade: Radial forward

Nominal power: 118 W

Acoustical data: 65 dB(A) DIN 45635-1 ISO 3745

Fan control eAir control: Stepless (supply and exhaust running separately)

Heat recovery

Heat exchanger type: Rotating heat exchanger

Heat exchanger material: Aluminium

Heat exchanger surface: 57 m²

Heat exchanger dimensions: 370 x 200 mm (60 μ)

Heat exchanger motor: 5 W

Ventilation unit annual temperature efficiency (EN 13141-7:2010): 79 %

Supply air annual heat recovery efficiency* (EN 16798-3:2017): 92 %

Extract air annual heat recovery efficiency* (D5:2012): 78 %

* supply air +18°C, extract air +21°C, exhaust air temperature limit -7°C

Other information

Material inside cover: Steel sheet, zinc coated

Material outside cover: Steel sheet, zinc coated

Standard electric after heater efficiency: 500 W

Sound level in supply air duct at fan speeds 20, 40, 60, 80 and 100% LWA: 39, 55, 65, 72, 75 dB(A)

LPA, dB(A), 10 m²: sound absorption: -, 32, 39, 45, 47 dB(A)

Positioning of the water-circulating after heater: in duct

Duct heater measurements (W×H×L): 313×255×356 mm

Positioning of a cooling (CG) coil: in duct

Duct cooler measurements (W×H×L): 415×330×396 mm

Do you need help choosing the right product?

We will gladly help you. Contact our customer service phone +358 9 4255 0305 (week days 8-16 UTC+2), e-mail: enervent@enervent.com or technical support phone +358 9 4255 0303 (week days 8-16 UTC+2), e-mail: service@enervent.com.